charpy impact test force on specimen|charpy v notch sample size : purchaser In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa. WEBAssistir Acredite em Mim: A História de Lisa Mcvey Online Dublado E Legendado HD 1080p - Império Filmes. Cinema TV, Drama, Filmes, Filmes Dublados, Filmes em .

{plog:ftitle_list}

webOne of the world's leading online gambling companies. The most comprehensive In-Play .

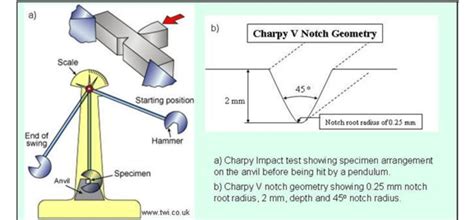

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test .The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be used as an economical quality control .

A new twist for Charpy testing: Force Verification Specimens • Additional information can be obtained from a Charpy impact test if the machine striker is instrumented .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa. This paper provides a critical review of existing applications of the Charpy method for impact testing of cementitious composites. Studies have employed various specimen .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

charpy v notch sample size

charpy impact test sample dimensions

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.

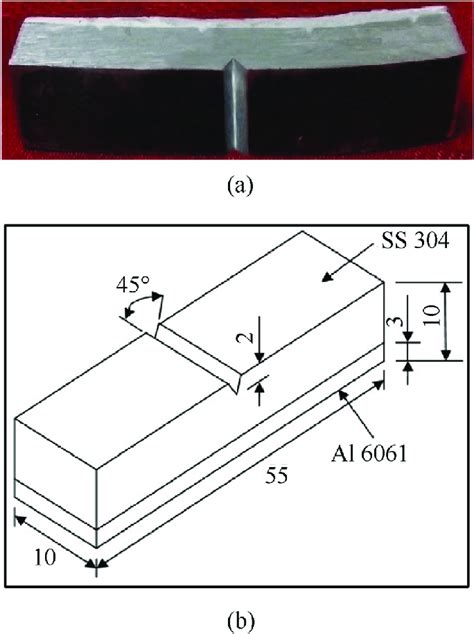

The Charpy impact test. The securely clamped standard size specimen is hit by a pivoting "hammer" with a pointed edge. The inset shows the specimen geometry. In order to do this .Fig.2 shows the Charpy Test Specimen Diagrammatically with the dimensions and Fig.3 shows the Charpy impact Test specimen after Impact test at different velocity ranges from 3.0 m/sec to 4.2m/sec on Tinius-Olsen Model T84 Pendulum Impact Tester and its Force-Time History are captured using the data acquisition system attached to the tester [2 .

charpy impact test sample

For a Charpy test, a notched specimen is centered on the supports horizontally with the notch facing away from the pendulum. The pendulum is released to strike and fracture the specimen. Depending on the objective, application and .The value of energy absorbed is read directly from a dial on the machine. A typical impact testing machine is shown in Figure. 1. Figure 1. Schematic of a Typical Charpy Impact Testing Machine. In carrying out a test, the .The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient . Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . Impact tests are designed to measure the resistance to failure of a material to a suddenly applied force. The test measures the impact .

charpy impact test pdf

The results show that pendulum velocity has negligible influence on Charpy impact test results; the maximum force and impact absorbed energy both have a highly linear relationship to specimen width; Charpy impact test is sensitive to striker geometry, the results measured by 2 mm-striker are obviously smaller than those of 8 mm-striker. deformation of the striker, which can be correlated to the force applied to the specimen during the impact test. • The force-time record from an instrumented Charpy test resembles that of a tensile test. • SRMs 2112 and 2113 (launched in 2012), as well as SRMs 2216, 2218, and 2219 (launched in 2014) allow customers to verify their A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after impact. . but a true dynamic calibration of the Charpy force measurements is lacking. “To address this, we are developing an SI . A Charpy impact testing apparatus, a device with a pendulum with various locking points at specified heights and a fixture to hold the test specimen, is used to determine Charpy impact strength. The standard test specimen is described in ASTM E23. It has a V-shaped notch cut into it.

A pendulum is released to strike the specimen. The height of the pendulum before and after passing through the sample is used to calculate the energy absorbed during the fracture process. . Charpy impact test results are measured in joules, the SI unit for energy. This is simply the amount of work performed by a 1-newton force pushing a .IZOD Impact Testing can be done up to 240 foot-pounds on standard single notch and type-X3 specimens. Charpy Impact Test. . methods of impact testing relate specifically to the behavior of metal when subjected to a single application of a force resulting in multi-axial stresses associated with a notch, coupled with high rates of loading and .Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).

55 mm), CVN, sub-size specimens corresponding to different fractions of the thickness of a standard Charpy specimen (3/4, 1/2, 1/4), SCVN, and scaled miniaturized specimens (Reduced Half-Size, RHS, geometry), MCVN. All tests were performed as instrumented impact tests, recording the force applied to the specimen during impact, Charpy Impact Test. In a Charpy test, a notched specimen is struck by a pendulum hammer swinging from a known height. The energy absorbed by the specimen during fracture is calculated by the difference in the pendulum’s height before and after impact. This energy absorption measures material toughness.

charpy impact test formula

CHARPY IMPACT TEST ISO 179 Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. The values recorded can be used for quality

measuring sample thickness

How Charpy impact tests are performed. Specimen Preparation: A small, standardized specimen, usually a rectangular bar with a V-shaped notch machined on one side.The notch creates a stress concentration that promotes fracture when impacted. The test setup includes a pendulum hammer, a notched specimen holder, and a digital or analog . 5.3 For this test method, the energy lost by the pendulum during the breakage of the specimen is the sum of the energies required to initiate fracture of the specimen; to propagate the fracture across the specimen; to throw the free ends of the broken specimen (toss energy); to bend the specimen; to produce vibration in the pendulum arm; to produce .

The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. . Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be : V-notch – A V-shaped notch, 2mm deep, with .

measuring sheet metal gauge and thickness all metals fabrication

The Charpy impact test relies on the potential energy of a . between; and (2) the direction of the impact force relative to the predominate fiber orientation [50]. . [50], and Kim et al. [15] have discussed specimen size requirements for impact testing of cementitious composites. Radomski suggested that the minimum dimension of impact test .Impact testing machine Standard charpy specimens (also called as ‘notch’ specimens) Furnace and thermocouple (to heat the specimen and increase its temperature) Liquid nitrogen (to lower the temperature of the specimen) Tongs (to hold and place the specimen at the centre of the anvil) Vernier calipers (to measure the dimensions of the specimen) The Charpy impact test is an experimental test used worldwide for characterizing the notch toughness of metals, and thereby their suitability for applications ranging from ship hulls and railroad tracks to nuclear reactor pressure vessels. A standard Charpy test measures the energy absorbed in fracturing a specimen impacted by a swinging hammer.

with certified test specimens is necessary to indirectly verify machine performance. To achieve the required accuracy, a well-defined target (master machine) for absorbed energy . maximum force in a Charpy impact test. Over the past five years, the Charpy program has supplied an average of 2000 reference

The Charpy test is used to determine the resistance capacity of metal (steel) specimens against the sudden impact of a pendulum that swung from a certain height. The Charpy impact is also known as the Charpy V-notch test because the specimen used in this test is cut at a certain depth in a ‘V’ [.] The standard size of a specimen for Charpy impact testing is 10 mm × 10 mm × 55 mm. A 2mm deep notch with an angle of 45° and a tip radius of 0.25mm is then machined into one face of the bar. These specifications have a very tight tolerance because the shape and size of the notch can have a significant effect on the results of the test.The compliance of a Charpy impact machine, C M, can be measured by means of a low-blow elastic test on an unnotched Charpy-type specimen, provided an instrumented striker is used. The resulting force/time and force/displacement test records can be analyzed according to threeThe Class D - Dual Column Charpy Impact Tester has a striking 16 mm thickness. This refers to the thickness of the component that delivers the impact force during the testing process. The 16 mm striking thickness is carefully designed to ensure a consistent and controlled impact on the test specimens.

Charpy to ISO 179-1 is the preferred test method on plastics within the standard for single-point data ISO 10350-1. The test is ideally performed on unnotched specimens with edgewise impact (1eU). Should the specimen not break during the test, any subsequent tests are performed with notched specimens.

measuring skinfold thickness

measuring skull thickness

webO SuperHQ é o melhor site para ler e baixar Quadrinhos, HQs e Mangás de Hentai, Eróticos e Adultos da internet com muito sexo e putaria para você se divertir!

charpy impact test force on specimen|charpy v notch sample size